You’ve been thinking about it. You know it’s time. You know your business needs it. You know you need to take a minute to assess your overstock inventory.

Holding on to surplus inventory for too long can hurt retailers, but you’re not stuck with stagnant shelves. With the right data and a few tricks, you can pinpoint overstock inventory and deal with it without forfeiting your entire investment.

To get you started on refreshing your inventory, we’ll go over:

- When inventory is considered overstocked or dusty

- How you can manage surplus inventory

- What causes surplus inventory

- How to get rid of old inventory

- 9 ways you can move overstock inventory

- How to avoid having surplus inventory in the first place

Save time on inventory management

Use our free spreadsheet to track and manage your inventory. Prevent mistakes and help yourself stay organized.

When is inventory considered dusty?

Inventory becomes dusty—Lightspeed’s way of referring to obsolete, surplus or overstock inventory—when it’s at the end of its product life cycle.

In other words, your dusty inventory is anything that isn’t selling anymore. Overstock inventory negatively impacts your inventory turnover ratio.

When exactly inventory becomes stale or overstocked can vary. Automobile parts retailers will have a longer product life cycle than fast fashion retailers, for example.

For most products, there is a hard cutoff: anything older than 12 months should be considered obsolete.

Why is it bad to have too much inventory?

Too much surplus inventory can be a sign of poor product management. That means you may be overbuying.

Holding on to inventory has four key costs:

- Capital cost: the total cost of the inventory items—the purchase price.

- Storage space cost: the cost of the storage space housing your inventory, such as a warehouse or extra storage outside of your physical location.

- Inventory service cost: the taxes and insurance costs of your inventory.

- Inventory risk cost: the risk of your inventory depreciating in value. The cost is the lost revenue you expected that inventory to bring in, but may not if it doesn’t sell fast enough.

When you overbuy and undersell inventory, you tie up your cash flow with these four costs. When that happens, you can’t refresh your shelves with new goods. Customers will soon learn that you have nothing new to offer and will start to visit less often.

Granted, not having enough inventory is also bad. Empty shelves offer your customers nothing new, just like stagnant shelves. The key is to have just enough inventory by only ordering as much as you need and by being proactive in dealing with your old or excess inventory, potentially through inventory liquidation.

How to find overstock inventory

Surplus inventory isn’t ideal, but if you’ve got it, you need to deal with it. Before you can make the big decisions, you need a way to measure your overstock inventory.

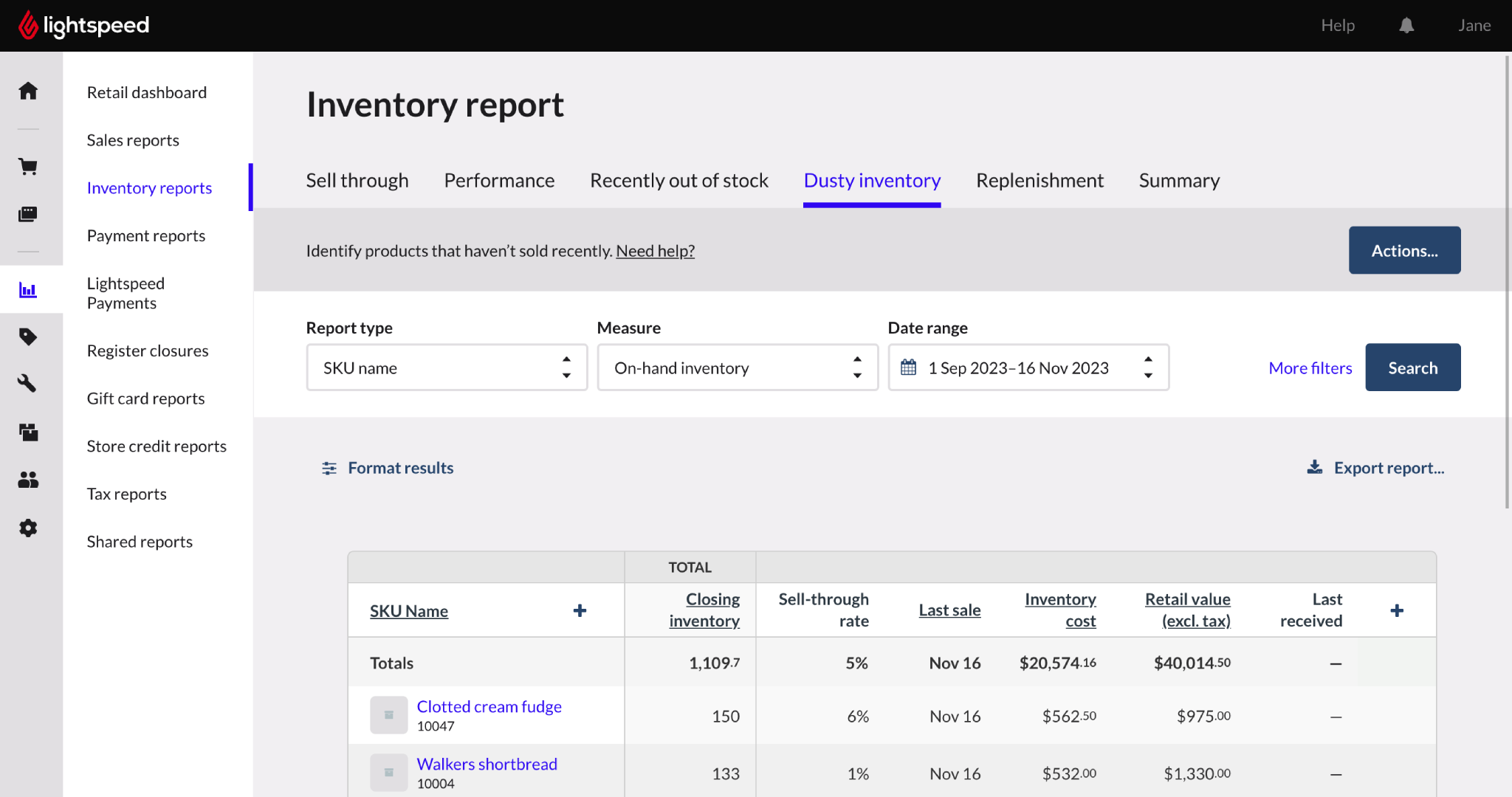

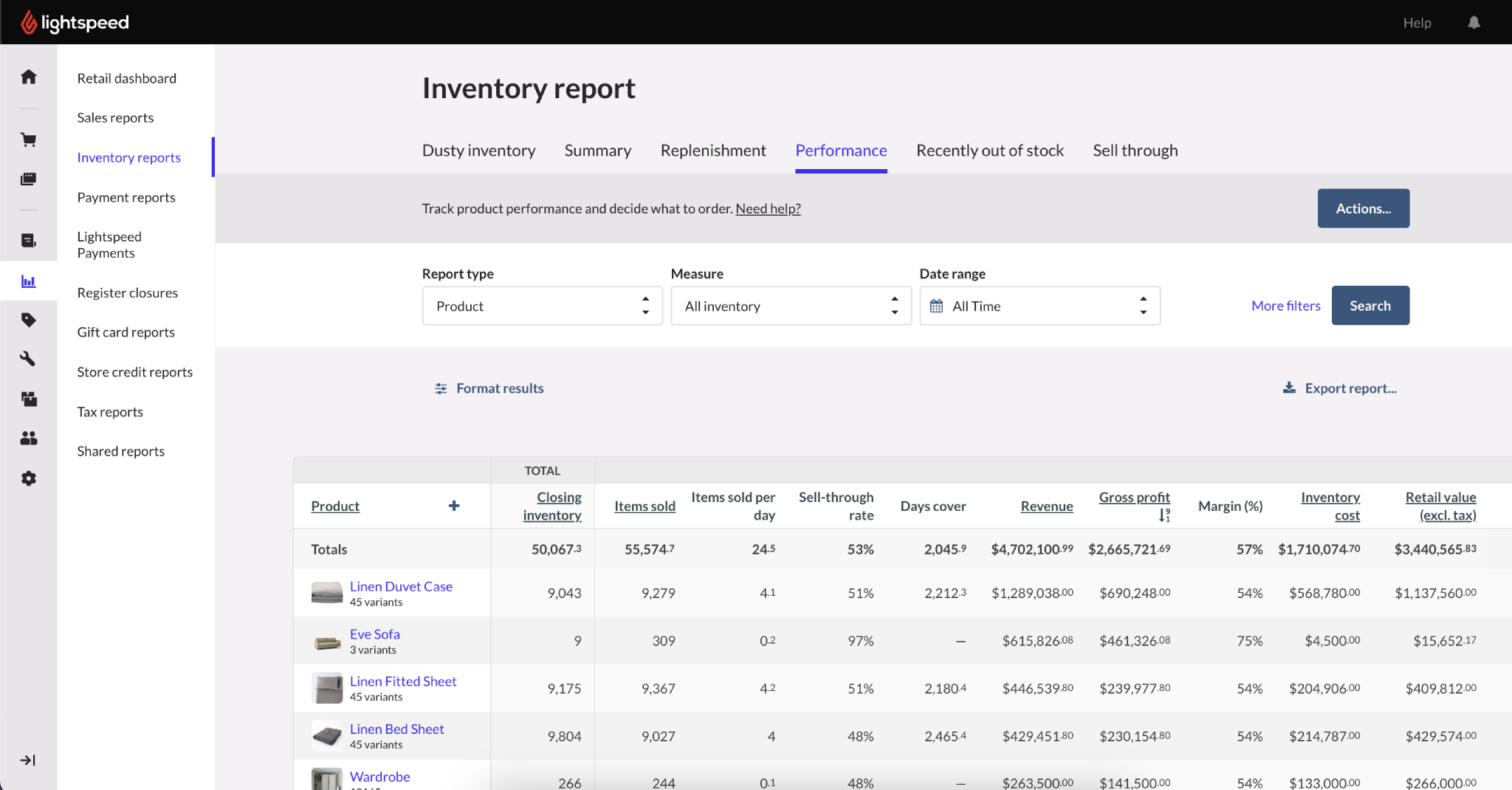

Lightspeed Advanced Reporting has two useful reports for finding surplus stock: the inventory performance report, which can shed light on any surplus inventory you may be carrying, or the dusty inventory report, which identifies any products that haven’t sold in a set time (typically six months).

How to run a product performance report

In Lightspeed, this report shows you the days cover metric—data that factors in your items sold per day and closing inventory to calculate how many days a product will take to sell out.

Let’s say you look up a product and the days cover column displays a lengthy time period; in this instance, you may be overstocking that particular item.

From there, you can sort items to see your best (or worst) performing products. You can also filter the reports based on product category, brand or store to dig deeper and compare different product types across multiple locations.

How to run a dusty inventory report

Sometimes, a product may not be selling at all. In that case, even if there’s only one left, it’s still overstocked—you don’t need it taking up space on your shelves or in your warehouse.

The dusty inventory report from Lightspeed will find that dead stock for you. All you need to do is run it.

By default, it’s set to measure in six month intervals. Depending on your industry’s sales cycle, you may want to set it for shorter or longer. After all, for a clothing store, inventory that sold six months ago but stopped selling three months ago may be dead, obsolete inventory.

What causes surplus inventory?

Every retailer deals with excess inventory eventually—but where is it coming from?

Here are the three main culprits.

Overstocking inventory

Some retailers overstock on purpose. This is a gamble; while it means you won’t have empty shelves in case of supplier or shipping delays (or holiday rushes on products), you could overshoot demand and end up with extra inventory at the end of the season.

Changing customer tastes

You tracked. You forecasted. You switched to a just in time inventory system, ensuring you’d never have excess stock.

And then a viral video convinced customers they want purple laces, not orange ones.

While you can track changing customer preferences over time, sometimes it happens fast, and you’re left with surplus inventory that’s suddenly selling slower than expected.

Incomplete inventory management

This is the big one: the main reason retailers end up with surplus inventory.

If you have the wrong data, you’ll make the wrong decisions. Incorrect or incomplete inventory counts will lead to under or overstocking as you order based on faulty logic.

Sometimes your calculations are off. If you’re forecasting demand using incomplete data or inefficient tools, you’ll end up with too much (or too little) inventory.

You may not have done any forecasting at all, which can also lead to excess inventory—taking a shot in the dark rarely works out. Inventory performance data will help make sure you order the right amounts in the future.

Finally, without correct inventory counts, you may be unaware of how much you actually have on hand. That can lead to reordering way over (or under) what you need.

To keep better track of inventory, make sure you’re:

- Using a cloud-based POS system that updates in real time across all your locations

- Performing regular cycle counts so the data in your POS is accurate and up to date

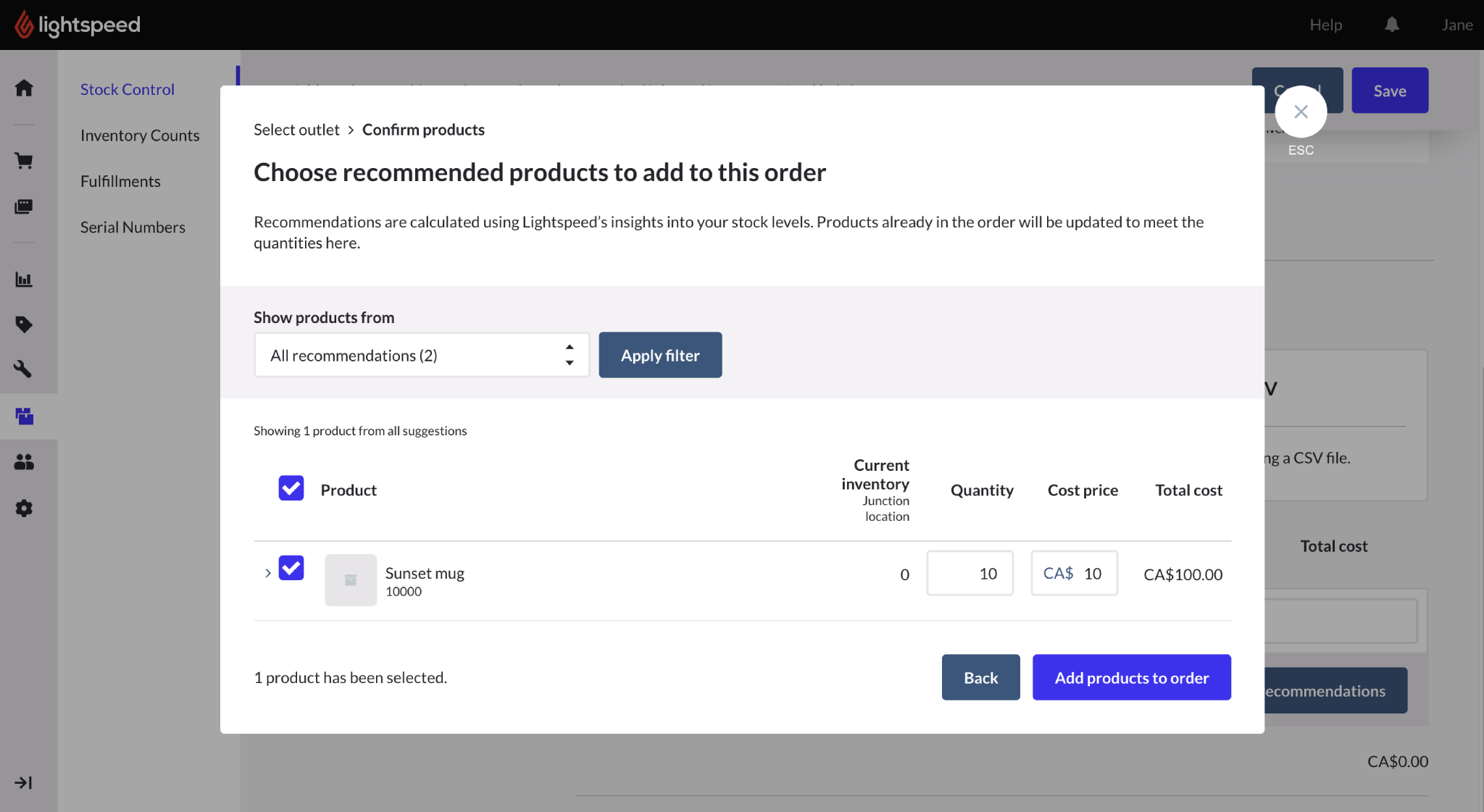

- Taking advantage of stock management tools, like Lightspeed’s reorder points and recommended reorder amounts

How to get rid of old inventory: what is inventory liquidation?

Inventory liquidation is the act of turning your inventory into liquid assets, and is the most common way of getting rid of old inventory. In other words, it’s selling old inventory for cash.

While sometimes associated with businesses closing down, inventory liquidation tactics can also be used to sell off obsolete and overstock inventory so you can bring in new goods for sale. You can either do it yourself or work with a third party, who buys your inventory and sells it in their own stores.

Liquidating your inventory is a little more involved than just cutting the price and calling it a day. You’ll need to consult your accountant so they log your actions correctly for your country’s accounting standards (GAAP in the United States, IFRS or ASPE in Canada).

9 ways you can move overstock inventory

Now that you’ve run your inventory report, it’s time to act on your data. The good news is surplus stock doesn’t have to be an immediate loss. There are ways you can still get a return of some sort from it.

1. Use the services of an inventory liquidator or off-price retailer

“As a retailer, your money is sitting in the product,” explains Tyan Parent, President of The Brande Group, a retailer who sells other companies’ excess stock. “Your bank account is in the product on shelves. If there’s no product getting out the door, your bank account is suffering.”

Don’t hold onto overstock inventory longer than you need to. Try using an inventory liquidator or off-price retailer to move your stock.

Inventory liquidators usually buy up inventory for businesses going out of business. However, some will also buy overstock inventory. If you’re having no luck moving your inventory on your own, you can contact an inventory liquidation company to sell off your goods.

Off-price retailers buy surplus inventory in bulk to resell, often apparel. Some focus on specific brands or audiences—The Brande Group, for example, works with designers who don’t want to damage the exclusive luxury perception of their brands with more obvious discounters.

While you likely won’t get back the initial price you paid for your goods by working with an off-price retailer or liquidator, you’re not losing your entire investment either.

Plus, by using these kinds of business, you can potentially extend your reach to new customers—shoppers who frequent The Brande Group’s stores are regularly introduced to new designer labels they can try out at a lower price before graduating to the designer’s own stores.

2. Transfer your surplus inventory to other locations

One store may be overstocked on a particular item, but that same product could be running low in another location. Analyze inventory levels across multiple stores and see if you can transfer excess products to other locations. Make sure you’re using a POS like Lightspeed to make stock transfers simple, ensuring your records stay correct in each location.

Even if you can’t move all your overstock inventory this way, you’ll have a chance to sell some of it without needing to discount it or give it away.

3. Adjust the way you showcase and price your overstock inventory

The layout of a store can impact how customers encounter (or do not encounter) the items in your inventory.

Is it possible to move surplus inventory to a different position in the store? Or to make it more prominent in your eCom store? Can you change the proximity to other items, or link to the overstock inventory on related product pages online? By increasing visibility to visitors, you will also increase the potential for unseen inventory to be found.

Pay attention to your retail analytics and the flow of traffic in your location, to figure out which areas of your store are frequented by shoppers. Use that information when deciding where to place your slow-movers.

As retail management consultant Judy Crockett advises, this could be an excellent way to freshen up your merchandise.

“Freshen the display, move things around, create new, brightly-colored signage and replace worn out price tags,” she advises. “Make it look new and fresh for your staff and customers–customers who may not have even seen the items in the previous location.”

Fashion retailer Vanessa Cooreman Smith of Flourish Boutique shares that they sometimes “re-market” slow-moving items in their stores. “We will re-photograph an item for the website, we will post a blog about the uses and advantages of the product, or we will display it differently in our brick and mortar store.”

If you determine that customers are finding the product just fine, but still the item is not moving, the next step is to determine whether there may be blockers to the purchase. This is when we can start looking at new pricing strategies.

Try repricing the items, whether that be via a discount, a sale or just a lower default price. You can also bundle the slow-moving items with related, popular goods for a higher price that still gives the customer a discount.

4. Discount slow-moving inventory

If remarketing or remerchandising doesn’t work, consider lowering prices of excess stock.

You can kick this tactic into high gear by creating a sale event. Why not run a flash sale to instill a sense of urgency in your customers? Or, if you have a ton of merchandise that you need to get rid of, consider running a store-wide event and aim to draw crowds to your store.

Judy recommends hosting a high-impact event with “lots of bells and whistles” to attract customers. “The bigger the event, the better, since sensing or seeing a crowd, implies huge deals, and instills an ‘if I don’t get it now it won’t be here later’ mentality and sales will soar. The sale becomes more about the event than it does discounts.”

Consider running BOGO or multi-buy discounts

A multi-buy offer is a type of sales promotion that allows customers to purchase products at discounted rates if they buy a certain quantity or amount. BOGO promos as well as offers like “Buy 3 get 1 free” are some common examples of multi-buy discounts.

This type of promotion can be very effective in moving excess stock, particularly if you’re selling commodities (like toiletries or home supplies) or merchandise that are purchased in sets (like clothes).

We can see an excellent multi-buy promo in action in the following example from the baby apparel retailer, Leo + Zo. Customers who purchase 3 sale items can enjoy an extra 15% off. The company has also made the promo extremely easy to redeem; shoppers can just pick out 3 eligible items and the discount will automatically be applied at checkout — no code required.

5. Offer the slow-moving inventory as gifts

Some items may not inspire their own way out the door if they’ve been there for long enough, but that doesn’t mean that the surplus inventory cannot be valuable to the store. Perhaps you can use it to help with customer loyalty, such as in the form of a gift accompanying another purchase.

While this does mean you’re not getting your money back for the goods in question, you are building positive customer sentiment. And if you clearly advertise a “gift with purchase” promotion online and in your store, you might convince browsers and window shoppers to convert. Everyone likes free goods, after all.

This tactic works best for low-cost items. You can also offer freebies as an incentive to either sign up for your mailing list or to increase their basket value (i.e. “Spend $75 or more and get a free bag”).

This is one of the tactics that Flourish Boutique implements in their stores if they find that a particular item is a “dud,” but doesn’t have such a high cost. “We’ll use it as a freebie or giveaway in event swag bags, in trade for people signing up for our email list or text service list, etc.” In doing so, Vanessa says that they’re essentially deploying the cost of the product as a marketing expense.

6. Make a charitable donation with the surplus inventory

Some inventory, failing to incite customer excitement, may also serve you well in the form of a donation to local organizations or initiatives. Depending on what you sell and what you’re looking to move, amateur sports, community kitchens, support groups or other local organizations might benefit from your donation of store inventory.

Making a charitable donation of your overstock inventory illustrates your store’s commitment to the community around you. Some charitable donations may also be tax deductible, so it’s a win-win for both your business and the organization you’re supporting.

7. Recycle your surplus inventory

If you’ve tried every possible way to rid yourself of overstock inventory and still find you have unwanted items on hand, you might have to eat the cost and recycle them.

This option should be your last possible resort. You make no money back, nor do you get a chance to reward your customers or give back to your community. But if you’re having no luck with any of the other methods, it’s better to free up your storage space for newer, fresher inventory.

8. See if you can return or exchange it

“When possible, return the merchandise to your vendor in exchange for credit or new merchandise,” adds Judy.

“If they sold you a dog, or the product simply was wrong for your market, make a case for returning it. Just be sure you are keeping the merchandise undamaged and in fresh packaging. Your vendor wants to keep you as a customer. Use that relationship to your advantage.”

If you have a great relationship with them, you should definitely explore this option. Just look at what OFY, a luxury men’s boutique in Miami, is doing. According to Ofir Farahan, owner of OFY, when certain styles aren’t selling, they work with their vendors and swap the merchandise.

“We’ve developed strong relationships with our vendors who will allow swaps,” he says. “They don’t want products sitting on the floor for so long, and obviously, we don’t, either. So we work hand-in-hand and try to find a way out.”

9. Sell them on online marketplaces

You can try to sell the items on sites such as eBay, Amazon, or Etsy. This route will require a bit of time, though, since you’ll have to create product pages and photograph each item (if you haven’t already done so), but these sites could be great avenues to help you move surplus stock.

Do note that each marketplace has its own rules and fees, so take note of the fine print before signing up.

How to avoid having surplus inventory in the first place

The best way to deal with excess stock is to try to avoid the issue altogether. Here are some quick tips for doing that:

Observe how customers interact with your merchandise

Ensure that you’re ordering the right products by keeping your customers’ needs in mind. Talk to them and observe their behavior so you can gain insights into what items will sell.

“As shoppers come into your store your sales staff should hear them make comments about fit, quality, etc. for a particular item — this will help clue them in as to why they do or do not like a particular item,” says Kat. “I would start off by talking to the sales staff to figure out what comments have been made and why the product isn’t moving.”

Forecast demand

Howard Forman, an Associate Professor of Marketing at California State University, Fullerton advises retailers to forecast demand. “Companies need to collaborate with customers and suppliers to more accurately forecast demand. Leveraging historical sales is an important element to demand forecasting.”

He continues, “They should also put as much emphasis on their inventory management by focusing on products that are moving the quickest and represents a bulk of revenue and profits. This will significantly reduce excess inventory.”

To make this work, arm your business with inventory management software that can track metrics like stock turn and sell-through. Knowing things like how fast stock is moving enables you to accurately forecast demand and avoid overstocking.

Be strategic about placing orders

A good rule to follow is to order lower quantities for non-basic styles. That’s what OFY does to minimize overstocks.

“We don’t seriously invest in a wide unit range for styles that aren’t classic pieces,” says Ofir. “For ‘pop pieces’ we’ll do say, 5 or 6 units. That keeps things fresh, and we don’t feel stressed out to get it off the floor. It’s in and it’s out, and if it does well, we’ll reorder it.”

See if your suppliers can ship directly to customers

“Merchants should also look to utilize direct ship options (from supplier to consumer direct), to avoid holding inventory all together,” says Matthew Davidson, Managing Partner at financial and operational consulting firm Conway MacKenzie.

One company that’s found success with this strategy is Wayfair, an online furniture store. Wayfair works with more than 7,000 third-party vendors that can ship products directly to consumers. This allows the company to showcase and sell millions of products on their website without physically stocking the merchandise.

Conduct inventory counts regularly

Regular inventory counts enable you to have a handle on your inventory levels, so you can anticipate stock movements. If you notice that certain product quantities aren’t moving, you can take action sooner and get them out the door before they become too old or stale.

An app like Scanner by Lightspeed can streamline your inventory counts by turning your iOS or Android device into a powerful stock counting device.

Scanner lets you and your team do full and partial inventory counts from anywhere in the store. You can count products simply by scanning their barcode through the app.

The skincare brand Neal’s Yard Remedies uses Scanner to manage their inventory, and doing so has done wonders for their inventory counting workflows.

“The stocktake process for us used to involve a lot of spreadsheets, and this wasn’t ideal because it leads to mistakes. Now with Lightspeed, people can use devices to scan easily and update the stock record,” says Paul Stephens, Head of Data & Technology, Neal’s Yard Remedies.

Give your overstock inventory new life

Your investment in inventory can yield all kinds of value, in terms of profits but also in terms of marketing and customer and community relations. By seeing both the tangible and the less tangible opportunities, there are many ways to have all your investments serve you best, even when your inventory goes dusty.

Don’t forget that however you’re choosing to move your overstock inventory, you’ll need to consult with your accountant about best practices for writing your inventory down or off.

If you’d like to learn how Lightspeed reports like Dusty Inventory can help you manage your store with data, let’s chat.

News you care about. Tips you can use.

Everything your business needs to grow, delivered straight to your inbox.

![11 Tips To Make Your Pop-Up Shop a Roaring Success [For Retail Store Beginners and Pros Alike]](https://blog-assets.lightspeedhq.com/img/2021/06/2da3ae10-blog-hero_pop-up-shop.jpg)