Inventory is the lifeblood of any retail business. Without products, you can’t have a store. The items you curate tell a story, build your brand, and generate revenue.

Like with most things in business, there’s a fun side to inventory, and there’s a less glamorous, but operationally important side to it. Nothing beats the excitement of deciding what you’re going to sell, finding vendors, examining samples, and placing your first inventory order.

However, it’s how you handle that inventory once it arrives – and after it sells out – that can make a big impact on the success of your business. Just-in-time (JIT) inventory management is a tried-and-true retail inventory management technique that can help your store improve efficiency and profitability.

If JIT is a foreign concept to you, you’ve come to the right place. In this guide to just-in-time inventory management systems, you’ll learn:

- What just-in-time inventory management is

- How JIT differs from other inventory management techniques

- How to implement JIT at your store

- How software can streamline inventory management

Save time on inventory management

Download our free inventory management spreadsheet template to organize and track your inventory, saving you time and preventing costly mistakes.

What is just-in-time inventory management?

Just-in-time (JIT) inventory management is an inventory management strategy that involves manufacturing products or reordering stock so that it arrives just as you need it.

JIT is an alternative to retail inventory management methods that involve ordering, or producing, more inventory than current customer demand dictates and storing it until you need it. With the just-in-time retail inventory management strategy, you receive products just in time to sell to customers, instead of days or weeks before you run out of your current stock.

Efficiency and cost effectiveness are the primary benefits of a JIT system. When you order exactly what you need, when you need it, (rather than stocking up on what you’ll need in the future) then you have less cash tied up in inventory. With increased cash flow, you have funds to invest in other aspects of the business, such as marketing or staffing, for example.

Furthermore, with less inventory on hand, you need less space to store it. A JIT system makes it possible to save on storage, which ultimately reduces your total inventory-related costs.

How does JIT differ from other retail inventory management techniques?

Just-in-time is just one of several techniques for managing inventory. The biggest difference between JIT and other inventory management systems is that JIT is a “pull” system, while the others are “push” systems.

Pull inventory control systems stem from customer demand, which means that inventory is ordered to meet actual demand. In some cases, this means waiting until the customer has made a purchase before creating or reordering a product.

In push inventory control systems, inventory is created (or ordered) in advance so that it’s ready to meet customer demand. With a materials requirements planning (MRP) system, for example, parts of products are made in advance, so that they can be assembled more quickly when forecasts predict there will be demand.

Optimize production technology (OPT) and flexible manufacturing systems (FMS) are other types of push systems.

Want to learn about other inventory strategies? Check out our inventory management guide.

How to start using JIT at your retail business

If you’re curious about implementing a just-in-time inventory management system at your store, we’ve outlined four quick steps to get started.

First, you’ll need to decide whether or not JIT is right for your business. Once you’ve determined that it is, you’ll need to implement inventory management software to keep things running smoothly. Next, you’ll need to forecast demand for your products. Finally, developing strong relationships with trustworthy suppliers will ensure everything goes off without a hitch.

Here’s a closer look at each step.

1. Decide whether JIT is right for your business

First things first: make sure JIT works for your store. Carefully consider the pros and cons of the system before committing to it.

On the plus side, a just-in-time system lets you have fewer funds tied up in inventory. When you spend less cash on inventory, you can also spend less on storage and handling, and can have more money to invest in other parts of the business.

With less inventory on hand, your business can be more efficient and agile. Let’s say you run a stationary and gifts store. Perhaps at the start of the year, avocados are very trendy. Everyone wants avocados on everything: cards, mugs, notebooks, etc. If all of sudden llamas become the hot new thing, but you’ve already invested in a year’s worth of avocado-themed products, then you won’t be able to phase out avocado products and have enough cash to introduce llama products.

Things change quickly in retail. A just-in-time system helps you stay nimble.

However, there are also drawbacks to JIT inventory management. If you run through your inventory more quickly than predicted, you risk facing a stockout. When you don’t have enough inventory to meet customer demand, then you lose out on the opportunity to generate revenue. You also run the risk of frustrating customers, and possibly losing them to competitors who have what they need in stock.

And, because JIT involves getting shipments in in the nick of time, it’s difficult to have a JIT system without reliable suppliers and accurate forecasting. We’ll share retail inventory management tips that will help you check those boxes in the next steps.

2. Implement inventory management software

You’ll need to run a tight ship to make sure you don’t run out of inventory before your next delivery arrives. Inventory management software can take a lot of the repetitive, manual parts of managing inventory and automate or facilitate them.

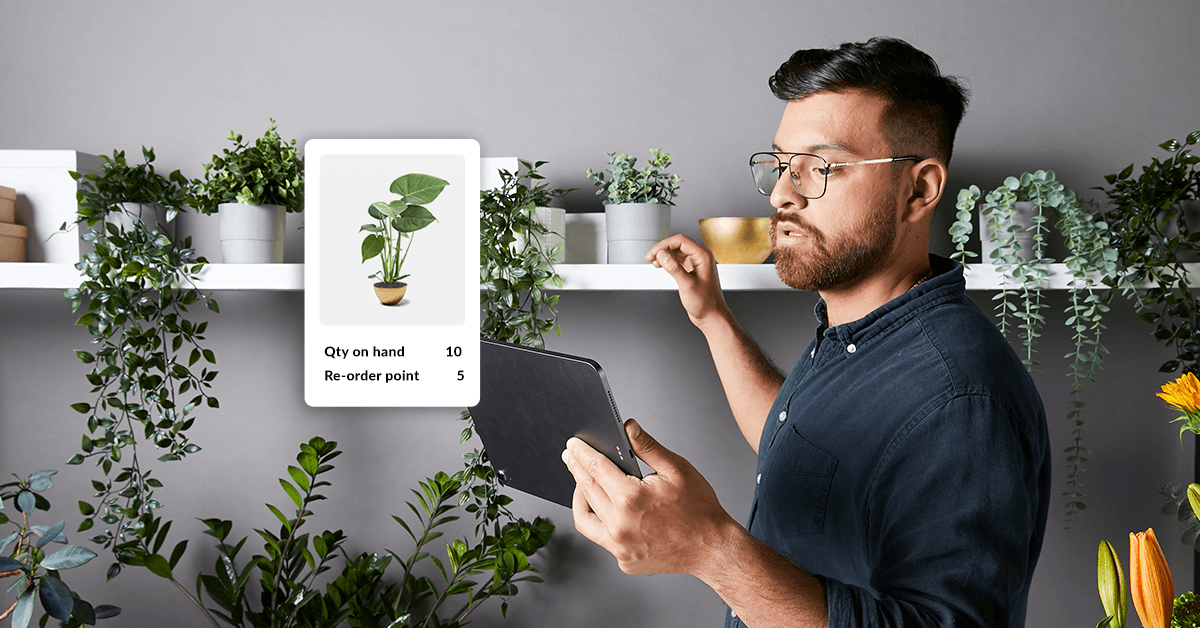

Look for a system that can help you implement reorder points and can alert you when it’s time to reorder inventory that falls below a certain level, with enough time to arrive before you reach a stockout.

3. Forecast your inventory needs

The better you can understand customer demand, the more accurately you can forecast your inventory needs and ensure you never encounter a stockout or overstocking. When you have just what you need – just in time to use it – you’ll be able to run your business more efficiently.

Use point-of-sale (POS) system data and inventory reports to understand your inventory turnover ratio, establish reorder points, and analyze trends in demand upticks.

4. Establish good relationships with suppliers

Successful execution of JIT depends on several internal and external factors. Accurate demand forecasting is the most critical internal factor, while making sure deliveries arrive when you expect them to is the most important external factor to JIT success.

The key to consistent deliveries is working with trustworthy suppliers, and maintaining good relationships with them. Ask fellow retailers to recommend reliable vendors. Direct introductions are best because they add accountability to the relationships.

If you’re working with large, wholesale suppliers, make sure they assign an account manager to be your main point of contact. They should alert you if there are any delays in production or shipping.

If you’re working with smaller suppliers, such as independent artisans, make sure they have the bandwidth to fulfill your orders, and communicate with you in case of delays.

How software can help you get started with JIT and streamline inventory management

Figuring out how much inventory you have in stock and when you need to order more is challenging and time consuming when you have to do it manually. Software can help. A retail POS system with inventory management features, or a POS that integrates with standalone inventory software, makes managing inventory more efficient.

This kind of software tracks sales data so you can more accurately forecast your inventory needs. It also makes it easy to keep an eye on current inventory counts.

With inventory software, you can set up reorder points for every item in your catalog. When you reach them, your system will notify you when you need to reorder stock. Some software can even automatically place those orders for you.

Wrapping up: Just-in-time inventory for beginners

Just-in-time is an inventory management strategy that involves reordering inventory or making products so that they arrive “just in time” to hit the shelves or be shipped to customers. JIT is a pull inventory system, which means that customer demand dictates production and orders. Conversely, push inventory systems, like materials requirements planning, optimize production technology, and flexible manufacturing systems, prepare inventory in anticipation of demand.

Before implementing JIT at your business, weigh its benefits and disadvantages to figure out whether it’s right for your store. On the upside, just-in-time inventory management allows for improved cash flow and agility. On the downside, JIT requires accurate forecasting and can make you vulnerable to stockouts.

If you’ve realized that JIT could work for your business, start by adopting inventory management software, forecasting demand, and establishing relationships with trustworthy suppliers.

Lightspeed Retail can streamline every aspect of inventory management, and make a just-in-time system easier to implement successfully. Watch a demo today.

News you care about. Tips you can use.

Everything your business needs to grow, delivered straight to your inbox.

![11 Tips To Make Your Pop-Up Shop a Roaring Success [For Retail Store Beginners and Pros Alike]](https://blog-assets.lightspeedhq.com/img/2021/06/2da3ae10-blog-hero_pop-up-shop.jpg)