As a retailer, your inventory is the heart of your business. When your stock is stagnant, business is stagnant—but when you’re smart about how you manage your inventory, you can keep the cash flowing and your customers happy. That’s why you know you need to keep on top of your inventory performance.

Knowing your inventory days on hand can help you a lot in that regard. Like knowing your inventory turnover ratio, your inventory days on hand keeps you informed of potential changes you might need to make to the way you operate.

In this post, we’ll go over:

- What inventory days on hand means

- How to calculate your inventory days on hand

- How to improve your inventory days on hand

Optimize your inventory setup

Become an inventory management master with our guide.

What is inventory days on hand?

Your inventory days on hand (DOH), also known as days of sales inventory, is exactly what it sounds like—the number of days your inventory stays in stock (on hand), on average. It’s a measurement of how quickly you go through your stock, which means it’s a measurement of how long the money you spend acquiring your inventory stays tied up in your inventory.

In other words, inventory days on hand is a measurement of your inventory liquidity.

The lower your DOH, the better, generally. A low DOH indicates you’re being efficient with how you purchase, store and sell your stock. When you get a new shipment of inventory, you’re selling through it at a rate fast enough that you don’t have a backlog of stock building up with every new shipment.

If you have a high DOH, you likely have dusty inventory on your shelves and a low inventory turnover rate.

Why is inventory liquidity important?

If you have poor inventory liquidity, customers are likely to see the same things available on your shelves every time they return. That means they’re likely to return less often, and your competitors will be better able to lure them away with newer products.

A lot of inventory liquidity means you can bring your customers new products and refreshed stock more often. It sets you up to be agile in how you react to customer demands.

Say, for example, you’re a fashion retailer that sells clothing and accessories for trendy young women. If you have a lot of inventory liquidity, you’re turning your inventory into revenue you can use to keep bringing in hot new trends and brands, keeping your apparel store on the cutting edge. If you have very little inventory liquidity, you’re in danger of losing your trendy edge, as the money you spend on inventory stays tied up in stock that isn’t selling.

What is the relationship between the inventory turnover and the number of days inventory on hand?

Inventory turnover and inventory days on hand calculations have an inverse relationship. If your inventory turnover is high, your DOH should be low.

Inventory turnover is the measure of how many times you’ve sold and replaced your inventory in a given period. It’s a calculation of how effective you are at selling the inventory you have. When you have a low inventory turnover, you know you need to change how you sell and manage your stock.

Inventory days on hand is more granular than that, because it’s a measurement of how quickly it takes you to clear out the inventory you have. If your inventory turnover helps you decide if you need to be more efficient about selling and managing your stock, your inventory days on hand helps you decide when you should reorder inventory, as you can predict how many days your stock will last.

How to calculate inventory days on hand

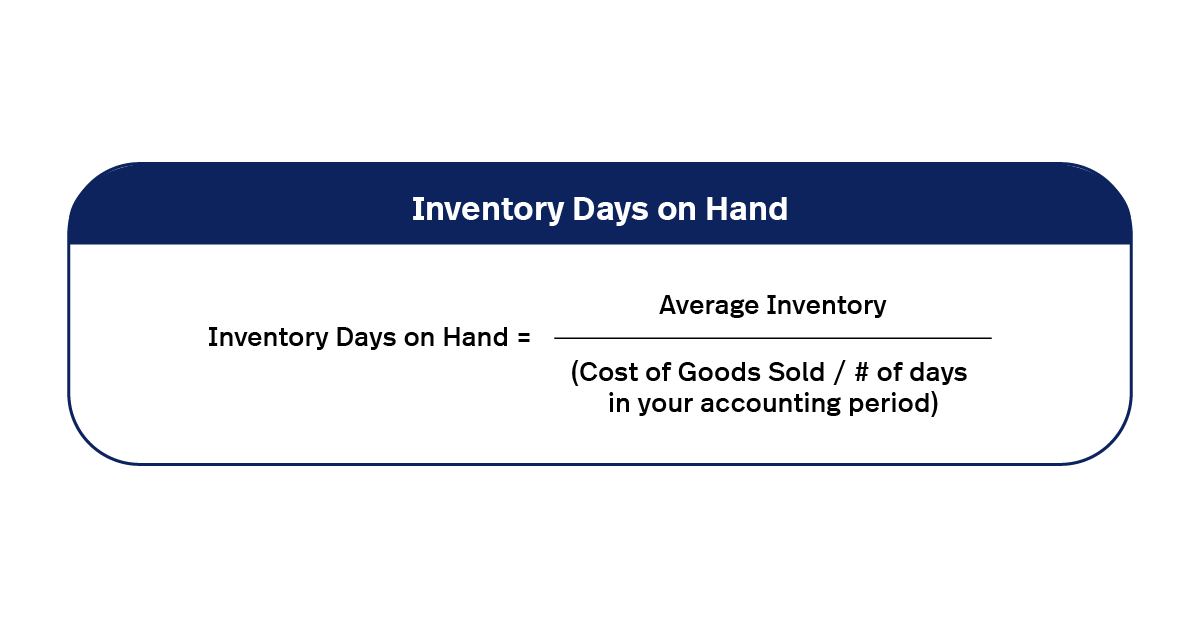

You can calculate your inventory days on hand with this formula:

Average Inventory/(Cost of Goods Sold/# days in your accounting period) = Inventory Days on Hand

Let’s break down how this works.

First, you need to pick the accounting period you’ll be calculating for. We pick this number first, because it will inform how we calculate the other numbers we need. If you want to determine your DOH for a year, use 365. If you want to see your DOH for a quarter, use 90.

Then, you need your average inventory. You can find that using this formula:

(Beginning Inventory + Ending Inventory) / 2 = Average Inventory

Your beginning inventory is the stock you had on hand at the beginning of the period you’re calculating. Your ending inventory is the stock you had on hand at the end of the period you’re calculating.

Finally, you need your Cost of Goods Sold (COGS) for the period. If you’re using Lightspeed, you can find this by running the built-in Totals report for the date range you’re calculating.

Once you have your numbers, plug them in and you’ll get your DOH.

Let’s say for a period of 90 days, we had a COGS of $100,000 and an average inventory of $30,000. First, we would divide our COGS by 90, which gives us 1111.11. Then, we would divide our average inventory by 1111.11, which would give us our DOH for the quarter: 27.

The inventory turnover method

If you know your inventory turnover ratio, you can calculate your DOH with this alternate formula:

# days in your accounting period/Inventory Turnover Ratio = Inventory Days on Hand

Say you want to know your average DOH per quarter, and you turn your stock 3.3 times a quarter. You’d divide 90 by 3.3 and see you have 27.3 days of inventory on hand on average.

How to improve inventory days on hand

So you’ve crunched the numbers and you feel your inventory DOH is too high. You might feel a DOH of 60 is tying your revenue up in inventory costs for a bit too long, and you want to bump it down to 30.

Take a look at how much you’re ordering and how often. You might be overstocking, which isn’t good for business—overstuffed shelves mean less new inventory, which bores customers, remember.

Try adjusting your reorder points to be lower, so you’re only bringing in new stock when you really need it. The only time you should have an excess of stock is when you’re anticipating extra demand—such as around the winter holiday season, where waiting to restock even a day might lead to more lost sales than otherwise.

Once you’ve adjusted your reorder points and purchase sizes, you’ll need to deal with any excess stock you currently have on hand. You could:

- Discount the stock. Try liquidating your excess inventory with discounts. The prospect of a sale catches the eye of budget-conscious customers.

- Bundle the stock. Get slow stock moving with either premade bundles (for example, pairing a slow-selling dishware set with a more in-demand punch pitcher) or with buy-one-get-one half-off sales.

- Donate it and write it off. If you have excess stock that’s been sitting on your shelves for too long and no one is biting, donate it and start over again.

Be careful not to overcorrect. Shortages are no good for the same reasons having too much stock is no good. You’ll drive away customers who can’t find what they’re looking for. If you have 10 days of inventory on hand, but it takes 14 days to receive new shipments and get them out on the floor, you need to increase your DOH, not decrease it!

What does days in inventory measure?

Days in inventory, also known as inventory days or days sales of inventory (DSI), is a metric that measures how long, on average, it takes for a company to sell its inventory.

“Days in inventory” and “inventory days on hand” are often used interchangeably, as they both measure the same concept—the average number of days it takes for a company to sell its inventory.

That said, some regions (like the United States) use “days in inventory” more commonly, while other regions use “inventory days on hand.”

What does months on hand measure?

“Months on hand” is another inventory management metric, similar to “Days in Inventory” or “Inventory Days on Hand,” but it expresses the result in terms of months rather than days.

It measures how many months’ worth of inventory a retailer holds on average before selling it.

The formula to calculate “Months on Hand” is:

Months on Hand = (Average Inventory / Cost of Goods Sold) * 12

How to improve inventory days on hand

Now that we’ve covered the fundamentals of inventory days on hand, let’s look at some of the ways you can improve it.

Reassess your ordering patterns

So you’ve crunched the numbers and you feel your inventory DOH is too high. You might feel a DOH of 60 is tying your revenue up in inventory costs for a bit too long, and you want to bump it down to 30.

Take a look at how much you’re ordering and how often. You might be overstocking, which isn’t good for business—overstuffed shelves mean less new inventory, which bores customers, remember.

Try adjusting your re-order points to be lower, so you’re only bringing in new stock when you really need it. The only time you should have an excess of stock is when you’re anticipating extra demand—such as around the winter holiday season, where waiting to restock even a day might lead to more lost sales than otherwise.

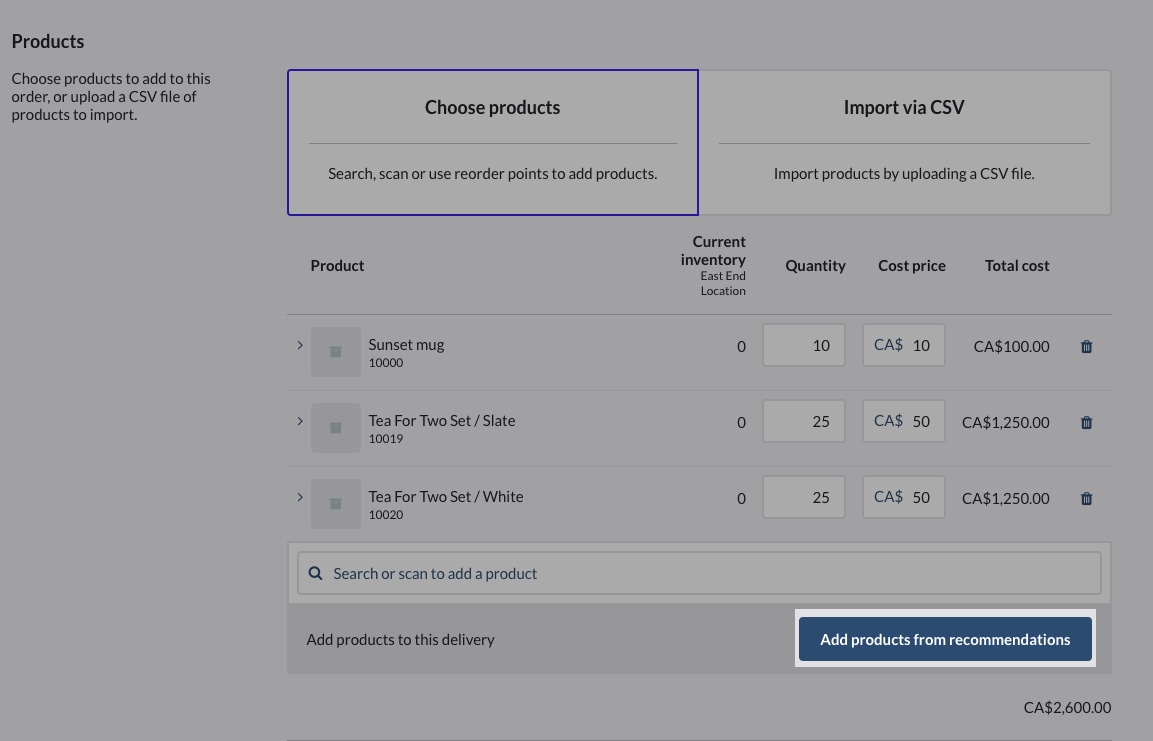

Using Lightspeed? You can easily add re-order points in the catalog section. Just click the product, head to the variant section and specify the reorder point and re-order quantity you’d like for that item.

Unload excess stock

Once you’ve adjusted your reorder points and purchase sizes, you’ll need to deal with any excess stock you currently have on hand. You could:

- Discount the stock. Try liquidating your excess inventory with discounts. The prospect of a sale catches the eye of budget-conscious customers.

- Bundle the stock. Get slow stock moving with either premade bundles (for example, pairing a slow-selling dishware set with a more in-demand punch pitcher) or with buy-one-get-one half-off sales.

- Donate it and write it off. If you have excess stock that’s been sitting on your shelves for too long and no one is biting, donate it and start over again.

Be careful not to overcorrect. Shortages are no good for the same reasons having too much stock is no good. You’ll drive away customers who can’t find what they’re looking for. If you have 10 days of inventory on hand, but it takes 14 days to receive new shipments and get them out on the floor, you need to increase your DOH, not decrease it!

Coordinate with your suppliers

When it comes to streamlining your inventory process, it pays to have great supplier relationships. Identify your key inventory vendors and work with them to streamline procurement processes, reduce lead times and improve order accuracy.

It’s also helpful to tap into their expertise around product trends and forecasts. Use their input to inform your inventory management decisions and ensure that you’re always carrying the right among of stock at all times.

Use the right inventory management software

Invest in inventory management software to track and manage inventory levels more efficiently. Use technology to automate some of the tips we mentioned above—including product reordering and inventory reconciliation.

City Bird, a gift shop based in Detroit, uses Lightspeed to manage their inventory and doing so has helped them stay on top of their stock ordering processes.

“The stock control feature in Lightspeed has really revolutionized our buying,” explains City Bird Founder Emily Linn.

“We used to use spreadsheets with complicated equations to see what we needed to reorder and it would take hours. And using that function, which auto generates amounts we need to reorder with, with numbers that you set, has allowed us to create preorders of products that are selling well and send them in in minutes.”

Mastering your inventory helps you master your business

Now that you know how to calculate your inventory days on hand, you’re one step closer to becoming an inventory management master.

The next step? Getting set up with a cloud-based system that does inventory unlike anyone else–that’s us. If you’re interested in learning how Lightspeed could help you manage your inventory in a more efficient way than ever before, let’s talk.

News you care about. Tips you can use.

Everything your business needs to grow, delivered straight to your inbox.

![11 Tips To Make Your Pop-Up Shop a Roaring Success [For Retail Store Beginners and Pros Alike]](https://blog-assets.lightspeedhq.com/img/2021/06/2da3ae10-blog-hero_pop-up-shop.jpg)